|

|

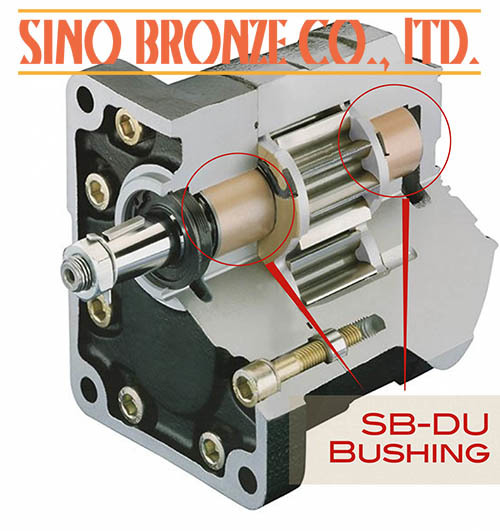

What is a Pump Bushing?

Pump bushings are specially designed bushings that fit into a groove in a pump. They are designed to maintain proper proportional spacing within the pump unit. Pump are complicated structures, with many different seals and areas where leakage is possible. Many parts are used to address potential leakage, and pump bushings are used to ensure that none of those parts interfere with the proper movement and functionality of the pump itself.

|

|

What is a Pump Bushing Used For?

Pumps use various forces, like suction, to complete their jobs. The forces involved in a pump’s role naturally require high quality sealing in their environments because sealing is what provides the highest quality suction for the entire pump and its shaft.

Pump bushings are one of the most important parts in the sealing system. The main pump bushing function is to properly seal off the pump body to prevent the escaping of air. Pump bushings can also be used to manipulate the size of the pump, using different sizes to allow more or less airflow into the pump. This can be referred to as choking.

|

|

What Are the Most Common Materials Pump Bushings are Made From ?

Pump bushings can be made of any material that other bushings are made of. This can include cheap metals like steel, expensive metals like bronze, bimetal, or synthetic materials like PFTE and Nylon. It depends largely on the type of pump that is being used, because the environment that the bushing will operate in largely determines the material that it will be made of. If there will be a lot of water or corrosive materials like dirt or sand, synthetic pump bushings or bronze pump bushings are probably a better bet than steel and brass pump bushings

Submersible Pump Bushing Sizes

|

|

Submersible pump bushings are pump bushings that can be fully submerged in fluid while still completing their job satisfactorily.

These are usually made of synthetic materials like nylon and PFTE because they are self-lubricating and are much more resistant to water damage. Their low friction coefficient is not heavily affected by the water, making them the best choice for submerged applications.

Submersible pump bushings come in all sizes, and they can be custom built to match your business or application needs. Pumps can come in every shape and size and serve countless functions, so it is important that you determine the ideal size and material for your pump bushing and order correctly.

|

Pump Bushing Failure and Removal

Like all parts, pump bushings do not last forever, and they will eventually need to be replaced. For most pump bushings, you will need to hire a professional to do the replacement for you. Replacing pump bushings is not an easy task and usually requires several specialized, industrial-strength tools. If you are not sure how to replace a pump bushing before reading this post, you should probably just hire someone who already knows how.

Pump Bushing Replacement and Install kit

If you think that you might be able to replace your pump bushing by yourself, you may want to consider using a pump bushing replacement and install kit. These kits are specially designed to provide you with all of the necessary parts to replace your failing pump bushing by yourself, and they work in most cases. Just be sure that the size and specifications of the kit you buy match with what you need.

|